- Reconcile material availability with scheduled production requirements

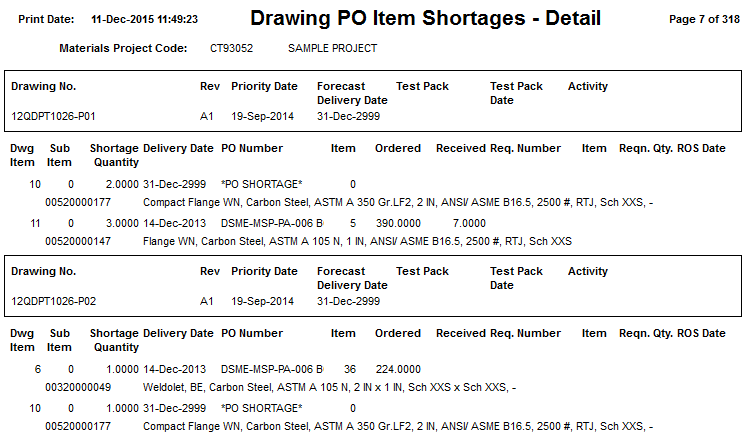

- Match receipts and orders to suggest material optimum usage and highlight expediting requirements

- Continuously manage material allocations and fabrication schedules to optimise productivity

- Avoid production bottlenecks and delays

Material Scheduling

Avoid fabrication bottlenecks

Sophisticated Material Control

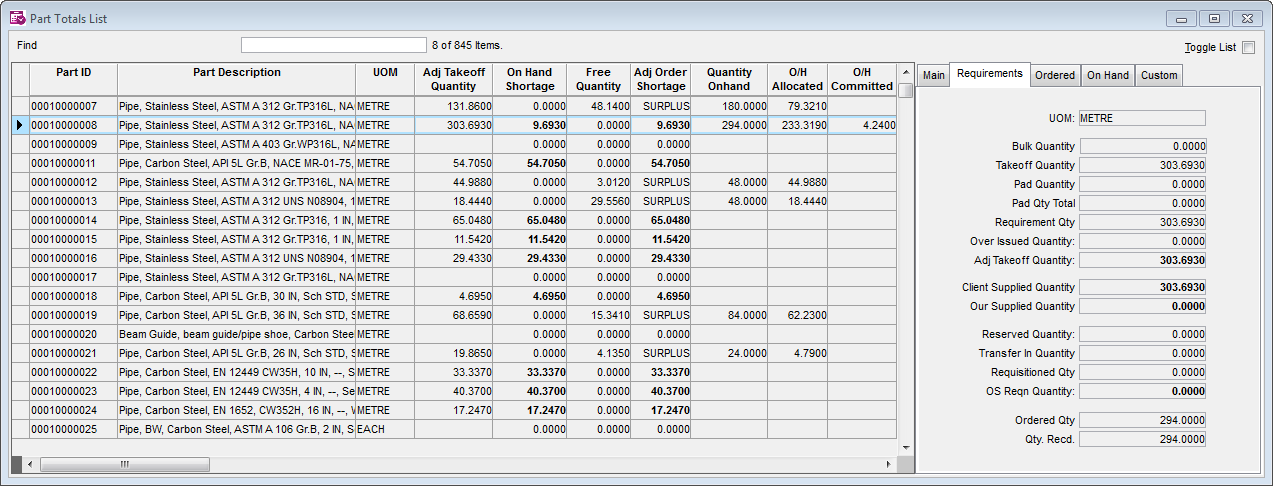

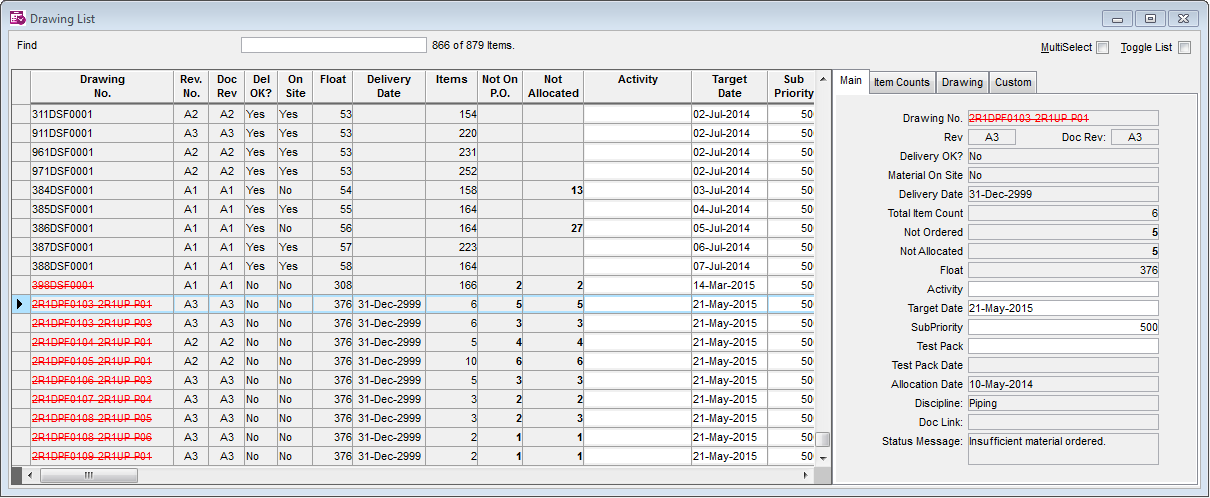

MatriX includes a sophisticated project material control system that reconciles the availability of material with scheduled production requirements. The system rapidly matches scheduled receipts and orders against prioritised material requirements to suggest optimum usage, highlight expediting requirements and provide look-ahead information to avoid future fabrication bottlenecks, delays and possible contention for available material.

Optimise productivity & remove roadblocks

Productivity & Control Tools For The Full Project Lifecycle

By combining essential materials information from procurement, material take off and planning, the impact of any changes in these key areas can be quickly assessed and action taken to ensure that any potential problems are dealt with before they occur.

The facilities may be applied as a productivity and control tool for planners and material controllers or they may be used as a primary input and control facility for the main operation functions of project materials management. As work progresses and the situation changes, MatriX can continually manage material allocations and / or activity schedules to optimise productivity.

Check the impact on the schedule

Look-ahead analysis tool

Look-ahead analysis allows the material controller or planner to check that the production schedule can be met. The system provides a powerful 'what if' facility, where details can be changed on a project wide basis in order to assess the overall impact on the project schedule.

The system also helps with creation of work packs and job cards (or specialised groupings such as pipe fabrication isometrics or spools).